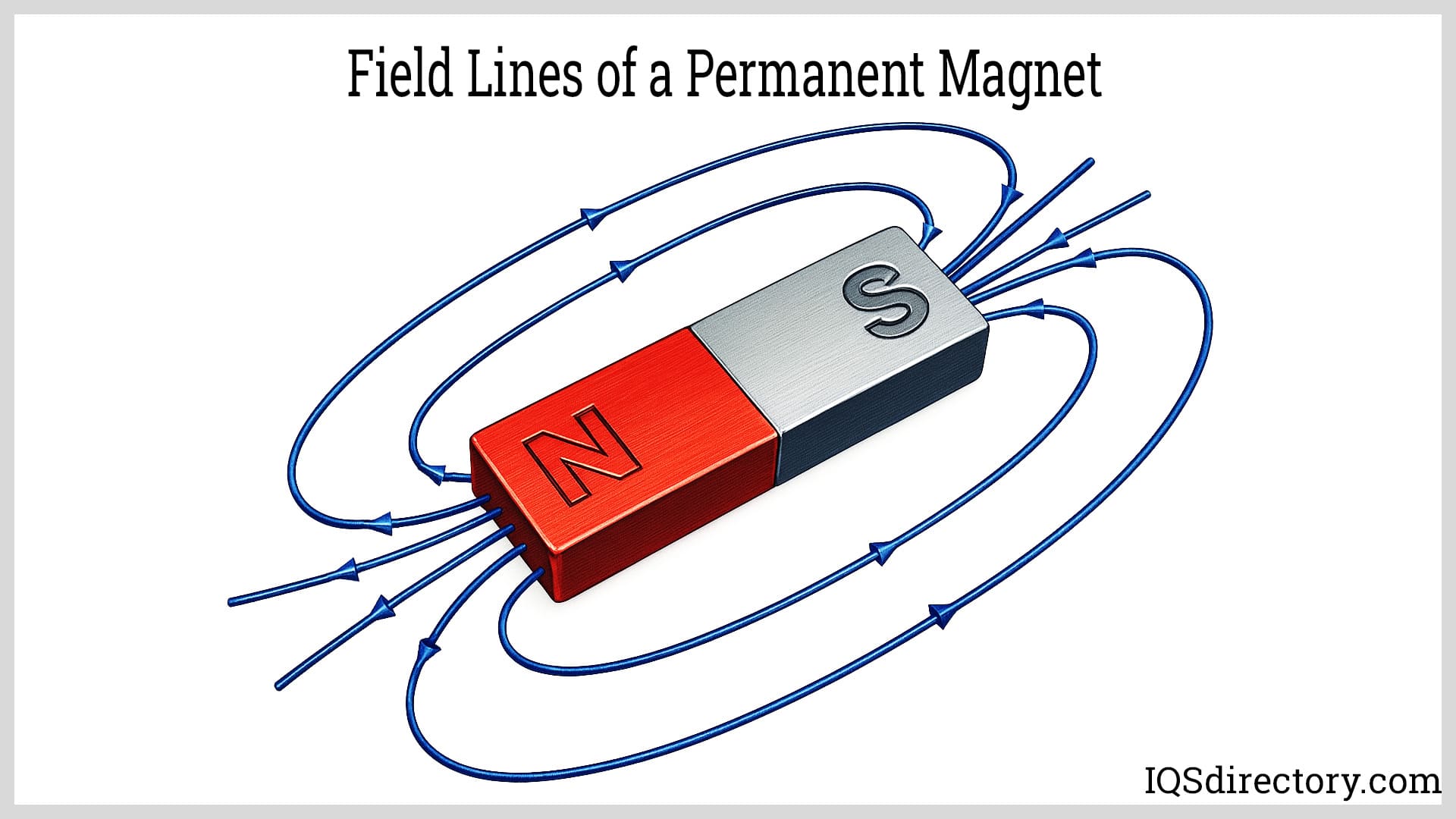

A magnet is defined as an object or piece of material that generates a magnetic field. The magnetic field is moving electrical charges that cause other magnetic objects to either be attracted to or repelled from the magnet. A tool or system that utilizes magnets or magnet combinations to perform a specific type of function is known as a magnetic assembly. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

At Applied Magnets, we are dedicated to providing some of the most powerful and reliable magnets available on the market. We specialize in high-grade neodymium magnets which are widely recognized for their unmatched strength and efficiency across a broad range of applications. From advanced engineering projects and industrial machinery to consumer products, scientific research, and educational...

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

Magnetic Specialties is a magnet manufacturer of magnet tools for the lifting & handling of materials & parts, industrial recycling and material separation applications. Products include magnetic grates, overhead magnets, tilting magnets, plate magnets, magnetic pulleys, magnetic drums and hoist magnets.

More Magnet Assembly Manufacturers

Applications of Magnets

Magnetic assemblies are integral components in modern industry, engineering, and everyday products. These precisely engineered devices serve specialized purposes such as magnetic holding, industrial lifting, separation of ferrous materials, magnetic mounting, and retrieval of metal objects. By combining different magnet types (such as neodymium, samarium cobalt, alnico, and ceramic) within well-designed assemblies, manufacturers can significantly amplify the magnetic force and tailor performance to specific industrial or commercial applications.

Across a broad spectrum of industries, magnetic assemblies offer solutions that streamline processes and improve product quality. In manufacturing and fabrication, magnetic assemblies are used for mounting, securing, and manipulating sheet metals and components. They are essential for material handling, where magnetic lifters enable the efficient movement of ferrous materials without direct contact, reducing risk and labor costs. In water treatment, magnetic separators remove unwanted metallic debris or contaminants, ensuring product purity and equipment protection. For lighter, everyday tasks, magnets power solutions like fridge magnets, magnetic whiteboards, and point-of-sale displays.

Many advanced systems and electronic devices rely on magnetic assemblies to function. These include:

- Electric motor activation and torque generation

- Eddy current separation in recycling and material sorting

- Blood tests and biomedical separations in laboratory equipment

- Linear actuators and motion control systems

- Ignition timing control in automotive applications

- Power consumption measurement in smart meters

- Industrial welding equipment operation

- Display technologies such as CRT and LCD TV monitors

- Environmental sensors and proximity switches

- Audio speakers and sound systems for high-fidelity reproduction

- Magnetic resonance imaging (MRI) for medical diagnostics

- Automotive components and electronic devices

- Biomedical and aerospace technologies

- Programming and erasing magnetic film/disks

Wondering which type of magnetic assembly is right for your application? Consider the strength, material composition, and intended use—from industrial automation to consumer electronics, each use case benefits from a targeted magnet solution.

The History of Magnet Assemblies

Modern magnet assemblies have evolved from humble origins. Their lineage traces back to lodestones, naturally magnetized pieces of iron ore that ancient civilizations used as primitive magnetic compasses. Early navigators—including the Greeks, Chinese mariners, and peoples of ancient India—depended on these tools for orientation and exploration. The term “magnet” entered the English language in the late Middle English period, borrowed from the Latin “magnetum,” reflecting the science’s spread across cultures.

By the 12th and 13th centuries, magnetic compasses were essential navigational aids for mariners worldwide, even though the principles of magnetism remained a mystery. The systematic scientific study of magnetism began in earnest in 1600 with William Gilbert’s work, “De Magnete,” which explored the effects of temperature on magnetism and introduced early techniques for magnet manufacturing. Gilbert’s pioneering insight—that the Earth itself is a giant magnet—laid the groundwork for centuries of innovation.

In 1819, Hans Christian Ørsted’s accidental discovery that an electric current produces a magnetic field sparked the birth of electromagnetism. This revelation inspired a wave of scientific and engineering breakthroughs in the 19th century, from the invention of the first electromagnets to the development of basic electromagnetic generators. As researchers explored the interplay between electricity and magnetism, magnet technology became foundational to industrial progress.

The 20th century brought transformative advances in magnetic materials and applications. Scientists such as J.J. Thomson and James Clerk Maxwell established theoretical principles that enabled practical innovations. Superconductor magnets, whose theoretical basis emerged in 1911, found real-world applications by the mid-20th century. The introduction of rare earth magnets in the late 20th century—most notably with the 1982 invention of the neodymium magnet by General Motors and Sumitomo Special Metals—revolutionized the industry. Neodymium magnets provided an affordable, incredibly strong alternative to earlier technologies like samarium-cobalt magnets.

Since the commercialization of rare earth magnets, manufacturers have continually improved the strength, durability, and versatility of magnet assemblies. In 2010, global production of rare earth metals exceeded 129,000 metric tons, a testament to their growing importance. Today, custom magnet assemblies drive progress in sectors ranging from high-tech electronics and automotive engineering to aerospace, medical devices, advanced robotics, and green energy applications.

Magnet Assembly Design

Effective magnet assembly design starts with choosing the right magnetic material. The most common options include:

- Ceramic (ferrite) magnets: Produced from sintered ceramic powder composites, mainly iron oxide combined with barium or strontium.

- Alnico magnets: Made from alloys containing aluminum, nickel, and cobalt, renowned for their durability and stability in high-temperature environments.

- Rare earth magnets: Neodymium iron boron (NdFeB) and samarium cobalt (SmCo), offering unmatched magnetic strength and reliability.

Manufacturers utilize various production techniques based on the magnet type and desired specifications. For example, ceramic magnets may be extruded, compressed, or sintered into custom shapes for precise applications. Magnet assembly design often requires balancing factors such as porosity, ease of fabrication, corrosion resistance, magnetic strength, and cost. Many suppliers also offer custom magnet assemblies for specialized industrial, scientific, or commercial needs.

When evaluating magnet assembly designs, consider these key factors:

- Required holding or lifting force

- Operating temperature range

- Environmental exposure (e.g., corrosive or humid conditions)

- Physical dimensions and mounting requirements

- Long-term magnetic retention

- Cost-effectiveness and availability of materials

Do you have complex design specifications or unique performance requirements? Contact a custom magnet assembly manufacturer or request a consultation to discuss your project.

Types of Magnets

Magnets come in a vast range of types, each engineered for unique industrial, engineering, or consumer applications. The right choice depends on critical properties such as magnetic strength, heat resistance, permanence, cost, and corrosion tolerance.

Magnets are broadly categorized as permanent magnets or non-permanent (temporary) magnets. Within these, there are specific classes:

- Electromagnets: Generate magnetism only when electrical current is applied. Used in motors, solenoids, transformers, and advanced automation systems.

- Superconducting magnets: Deliver exceptional strength but require extreme cooling, ideal for MRI machines and scientific research.

- Ceramic (ferrite) magnets: Inexpensive, corrosion-resistant, and used in everything from fridge magnets to electric motors.

- Alnico magnets: Durable and stable at high temperatures, often used in sensors, instruments, and audio equipment.

- Rare earth magnets: Neodymium and samarium cobalt magnets offer the highest strength-to-weight ratio, powering everything from headphones to wind turbines.

Magnets are also classified by shape and function, including sheet magnets, bar magnets, flexible strips, and bipolar assemblies for specialized requirements.

Permanent magnets maintain their magnetism indefinitely, without the need for an external power source. They are foundational to countless products and industrial systems.

Non-permanent magnets (including electromagnets and temporary magnets) become magnetized only in the presence of a strong external field or electric current. They are widely used in electronic devices, relays, and control systems.

Electromagnets are indispensable in automation, robotics, and manufacturing, allowing precise control over magnetic force. Their “on/off” capability makes them ideal for applications like magnetic clamping, magnetic separation, and linear actuators.

Superconducting magnets offer unparalleled field strength, crucial for heavy-duty applications in medical imaging (MRI), particle accelerators, and high-capacity magnetic separators.

Ceramic magnets (ferrite magnets) are cost-effective and corrosion-resistant, commonly used in magnetic tools, chucks, speakers, and small motors. Their lower magnetic strength is balanced by affordability and durability.

Alnico magnets are prized for their longevity, stability under changing temperatures, and easy machinability. They are common in sensors, meters, and vintage audio equipment.

Rare earth magnets—including neodymium and samarium cobalt—are highly sought after for their exceptional strength and ability to retain magnetism over time. Despite higher costs due to material scarcity and complex processing, they are indispensable for high-performance industrial, medical, military, and consumer electronics applications.

Seeking a deep dive into rare earth magnet options? Explore types, properties, and sourcing tips for rare earth magnets.

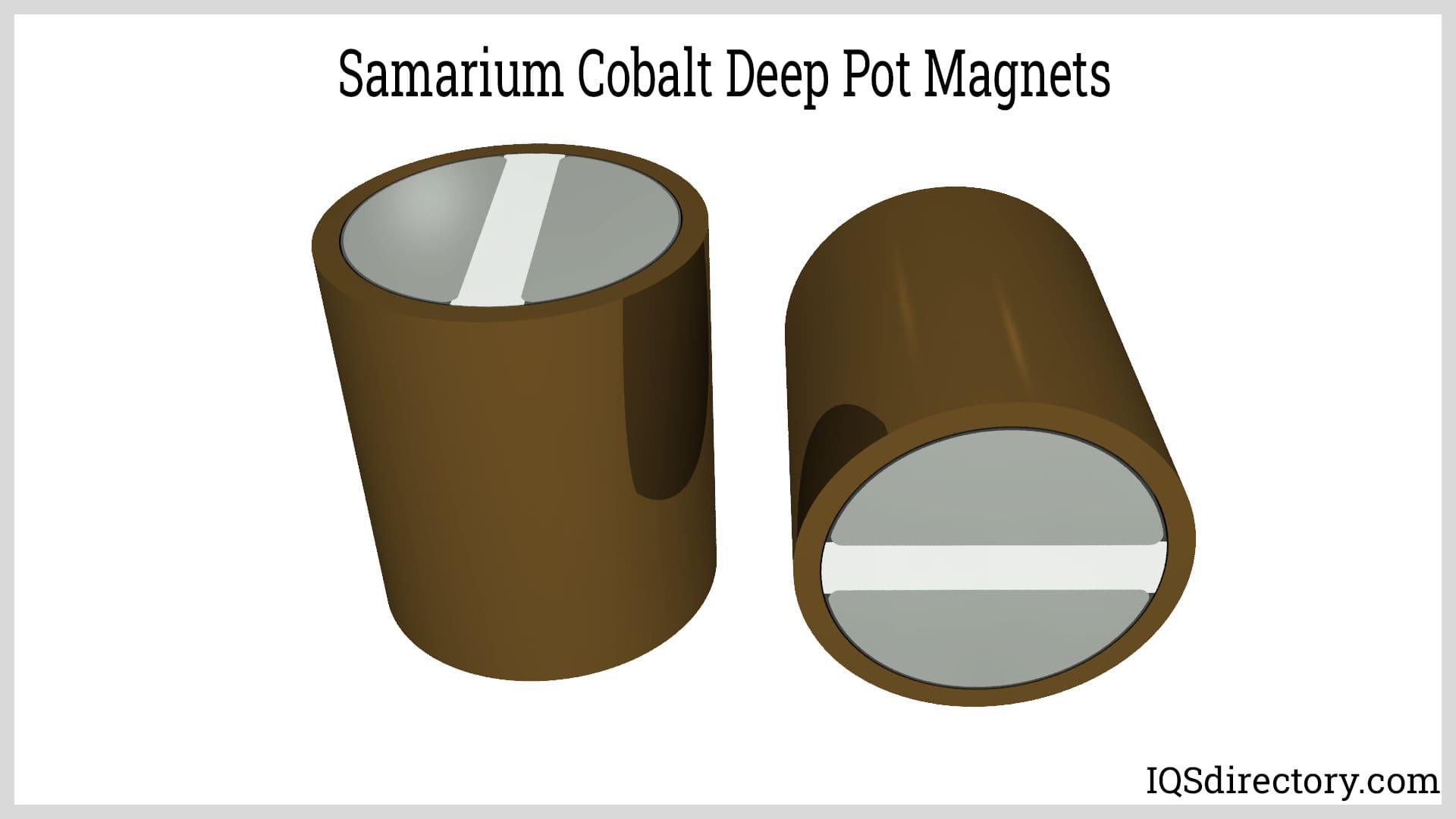

Samarium cobalt magnets are known for their resilience against demagnetization and corrosion, as well as their high thermal stability (up to 550℃). This makes them a preferred choice for aerospace, defense, and high-temperature industrial motors.

Neodymium magnets are the strongest commercially available permanent magnets. Their powerful magnetic fields are essential for miniaturized electronics, high-efficiency motors, sensors, and holding systems. However, they must be protected from corrosion and brittleness—often by nickel plating or special coatings.

Sheet magnets are flexible, easily cut to size, and ideal for signage, displays, and automotive applications. They combine ferrite powder and plastic binders, providing a versatile, low-cost solution for mounting and labeling.

Bar magnets are the classic magnet form, used in education, industrial detection, and simple holding tasks. Constructed mainly from ferrite or alnico, bar magnets are reliable for general-purpose magnetism.

Strip assemblies feature thin magnetic strips (often rubber-based) with adhesive backings, perfect for sealing doors, windows, or attaching signage to irregular surfaces.

Bipolar assemblies are robust magnetic structures designed for alignment, secure fastening, and high-temperature environments, common in manufacturing and engineering settings.

Not sure which magnet type suits your needs? Ask yourself:

- What is the required strength and size?

- Will the magnet be exposed to heat, moisture, or chemicals?

- Is the application static or dynamic?

- Is cost or performance the primary concern?

Advantages of Magnet Assemblies

Choosing the right magnet assembly can dramatically improve efficiency, safety, and product quality in your operations. Some key benefits include:

- Efficient sorting and separation: Magnetic assemblies quickly identify and extract ferrous metals—such as stainless steel and carbon steel—from non-ferrous materials, streamlining recycling and manufacturing processes.

- Cost-effective maintenance: By preventing metal contamination and reducing equipment wear, magnets lower maintenance costs and extend product lifespans.

- Contamination control: In food, pharmaceutical, and chemical industries, magnetic assemblies help protect against contamination by trapping metal particles during processing and storage.

- Enhanced workplace safety: Magnetic lifters and separators reduce the need for manual handling, minimizing injury risk.

- Time and labor savings: Automated magnetic systems speed up production lines and reduce manual inspection requirements.

Are you evaluating magnetic solutions for your facility? Contact a supplier about custom assemblies or request a quote to compare available options.

Magnet Assembly Accessories

To maximize performance and longevity, many magnet assemblies are paired with specialized accessories. These include:

- Adhesives and mounting hardware for secure installation in machinery, displays, or fixtures

- Connectors and brackets for integrating magnets into larger assemblies or automation systems

- Protective covers and coatings to enhance corrosion resistance and safety

- Ferrous inserts and backplates to concentrate magnetic fields or facilitate attachment

Looking for ways to improve your assembly? Explore compatible magnetic accessories to enhance durability and function.

Uses for Magnet Assemblies

When working with magnet assemblies, safety should always be a top priority. Magnets, especially high-strength rare earth types, can cause injury or interfere with sensitive electronics if mishandled.

Best practices for safe handling:

- Wear gloves to protect skin from cuts and abrasions, especially with brittle or strong magnets.

- Use safety goggles during assembly or machining to shield eyes from potential fragments.

- Avoid magnet exposure if you use a pacemaker or medical device—strong magnetic fields can interfere with electronic medical implants.

- Keep magnets away from mobile phones, credit cards, and sensitive electronics to prevent data loss or malfunction.

- When transporting magnets, use isolating containers to avoid accidental attraction to metal surfaces or disruptions to navigation systems.

- If allergic to metal dust, wear respiratory protection, and ensure proper ventilation in workspaces.

- For those with contact allergies, opt for protective clothing or delegate tasks as needed.

What are the most common safety risks when using industrial magnets? Review manufacturer guidelines or consult with a workplace safety expert for best practices specific to your environment.

Types of Magnets Used in Speakers

Magnets are essential to the function and performance of loudspeakers, headphones, and audio transducers. The type and strength of the magnet directly influence sound quality, volume, and frequency response. Speaker magnets typically range from 0.001 to 1.5 teslas, with different materials offering unique tonal characteristics.

Neodymium magnets are the most powerful rare earth magnets used in audio applications. Their high magnetic strength enables miniaturization, making them ideal for compact, lightweight headphones and tweeter drivers that require precise, high-frequency performance. Neodymium magnets deliver exceptional tone quality with fast, accurate frequency response, though their brittleness requires careful handling and protection.

Ceramic or ferrite magnets are larger and heavier but cost-effective. They are commonly used in speaker drivers for mid-range and high-power woofers and subwoofers. Their robust design allows for clear sound reproduction at high volume and excellent resistance to corrosion—ideal for marine or outdoor speaker systems. Ceramic magnets are also popular in mass-produced audio equipment due to their reliability and affordability.

Alnico magnets provide a classic, warm sound and are known for their resilience against cracking, thermal stress, and corrosion. They are a favorite in vintage and high-end horn speakers, as well as certain musical instrument amplifiers. Alnico’s easy magnetization also allows for fine tuning of acoustic properties.

When choosing a speaker magnet, consider:

- Required sound pressure level (SPL) and frequency response

- Speaker size and intended application (headphones, tweeters, woofers, subwoofers)

- Durability and environmental exposure (indoor, outdoor, marine)

- Budget and desired sound signature (warmth, clarity, volume)

Want to compare speaker magnet types? Research neodymium, ferrite, and alnico magnets for audio—find the best fit for your sound requirements.

Larger magnets are generally needed for bigger speakers, especially subwoofers, to drive the cone and achieve deep bass. However, overall sound quality depends not just on magnet size but also on enclosure design, voice coil heat resistance, and crossover networks. In high-end audio systems, multiple magnet types and driver sizes are often combined to optimize performance across the frequency spectrum.

Proper Care for Magnet Assemblies

To ensure maximum lifespan and performance of your magnet assemblies:

- Regularly test load-bearing magnets to confirm they retain their specified holding or lifting force

- Implement routine cleaning and decontamination—different magnet types may require specific solvents, lubricants, or protective coatings

- Protect assemblies from harsh chemicals, moisture, or extreme temperatures as much as possible

- Consult your magnet supplier for recommended maintenance practices and compatible cleaning agents

Looking for detailed care instructions for your specific magnet assembly? Request maintenance guides or technical support from your manufacturer.

Finding the Right Magnet Manufacturer

Are you searching for custom magnetic assemblies or industrial magnets tailored to your needs? Partnering with the right magnet manufacturer is essential to ensure product quality, reliability, and on-time delivery.

Consider these factors when evaluating magnet assembly manufacturers:

- Experience: Seek suppliers with a proven track record in your industry or application.

- Customization: Do they offer tailored solutions, prototyping, and design support?

- Production capacity: Can they handle your required order volume and delivery schedule?

- Compliance: Are materials and processes certified to relevant standards (e.g., ISO, RoHS, REACH)?

- Technical support: Will you have access to expert guidance throughout your project?

- Pricing and lead times: How do their costs and turnaround times compare to competitors?

Narrow your search to three or four qualified suppliers. Discuss your requirements in detail, including desired materials, dimensions, tolerances, and any unique challenges. After comparing proposals, select the manufacturer offering the best combination of quality, service, and value.

Ready to get started? Browse our list of leading magnet assembly manufacturers to request quotes, download product catalogs, or schedule a consultation.

Frequently Asked Questions About Magnet Assemblies

- What is the difference between neodymium and samarium cobalt magnets? Neodymium magnets are stronger but less temperature-resistant and more prone to corrosion. Samarium cobalt magnets excel in high-heat, corrosive environments and offer better long-term stability.

- Which magnet type is best for medical or food processing applications? Rare earth and ceramic magnets with appropriate coatings are often recommended for these industries due to their strength and corrosion resistance.

- How can I prevent magnet assemblies from losing strength over time? Store magnets properly, avoid excessive heat and mechanical shock, and choose materials rated for your operating conditions.

- Can I order custom-shaped magnets? Yes—many manufacturers offer custom fabrication to meet unique size, shape, and magnetic field requirements.

- What certifications should I look for in a magnet supplier? Look for ISO certification, RoHS compliance, and industry-specific standards as relevant to your sector.

Still have questions? Contact a magnet assembly expert or visit our manufacturer directory for more information.

Magnet Assemblies for Emerging Technologies

With the rapid advancement of technology, magnet assemblies are critical in the development of next-generation solutions:

- Renewable energy: Wind turbine generators and electric vehicle motors rely on high-strength neodymium magnets for efficiency and compact size.

- Robotics and automation: Magnetic sensors and actuators enable precise movement and feedback control in smart manufacturing environments.

- Medical devices: MRI machines, surgical tools, and lab automation systems use specialized magnet assemblies for accuracy and safety.

- Aerospace and defense: Magnet assemblies provide critical functionality in avionics, navigation, propulsion, and satellite systems.

Interested in how magnet assemblies can advance your innovation? Request case studies or technical whitepapers from leading manufacturers.

Check out our Linear Actuators website for more information on advanced automation components.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services