These magnets combine thermoplastic and thermoelastomer resins with magnetic powders in order to create injection molded, flexible magnets. These magnets are great for custom applications where a traditional, solid magnet would not offer the same type of value. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

At Applied Magnets, we are dedicated to providing some of the most powerful and reliable magnets available on the market. We specialize in high-grade neodymium magnets which are widely recognized for their unmatched strength and efficiency across a broad range of applications. From advanced engineering projects and industrial machinery to consumer products, scientific research, and educational...

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

Magnetic Specialties is a magnet manufacturer of magnet tools for the lifting & handling of materials & parts, industrial recycling and material separation applications. Products include magnetic grates, overhead magnets, tilting magnets, plate magnets, magnetic pulleys, magnetic drums and hoist magnets.

More Bonded Magnet Manufacturers

Injection molding is not the only process in which bonded magnets are created as bonded magnet manufacturers also utilize the compression bonding process in order to supply customers with a higher magnetic output. The trade-off between the two being that while compression bonded magnets offer a higher magnetic output, they are limited in the shape and sizes whereas injection molded magnets are rather flexible.

These bonded magnets are great for a wide range of applications from sensors to brushless DC motors and just about everything else in between. The two different processes used to create the bonded magnets, injection molding and compression bonding, yield different characteristics when it comes to their final product.

For example, a bonded magnets that is manufactured through the injection molding process has a very high mechanical strength, meaning it has a high tensile strength or that it can withstand a great amount of physical force. Compression bonded magnets on the other hand yield only a moderate amount of mechanical strength, but keep in mind that compression bonded magnets offer higher magnetic strength which can be attributed to their higher magnetic particle density.

There are many options when searching for the right type of bonded magnet for your application and a lot of factors to consider when making that choice. The type of applications and your requirements are the most important to consider. Ask yourself questions such as: Will the magnet be exposed to extreme temperatures? Will the magnet be exposed to solvents or outside fluids? Can my application fit a traditional style magnet or do I require a more flexible solution?

All of these questions are a great start to finding the perfect bonded magnet solution. Once you know what you are looking for, finding a trusted bonded magnet manufacturer is the next step in the process. They can help you fine tune your selection in order to better fit your application and will ensure that you receive the best possible bonded magnet based on your needs and requirements.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

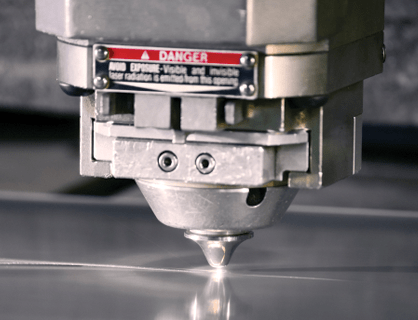

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services