Flexible magnets are perhaps some of the most interesting magnets on the market. As their name suggests, these magnets are flexible, meaning that they have the ability to be bent and manipulated in order to fit a specific application or use. In addition to this, flexible magnets also have the ability to be cut to virtually any shape desired which makes them the go to magnet for custom applications. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

At Applied Magnets, we are dedicated to providing some of the most powerful and reliable magnets available on the market. We specialize in high-grade neodymium magnets which are widely recognized for their unmatched strength and efficiency across a broad range of applications. From advanced engineering projects and industrial machinery to consumer products, scientific research, and educational...

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

Magnetic Specialties is a magnet manufacturer of magnet tools for the lifting & handling of materials & parts, industrial recycling and material separation applications. Products include magnetic grates, overhead magnets, tilting magnets, plate magnets, magnetic pulleys, magnetic drums and hoist magnets.

More Flexible Magnet Manufacturers

Flexible magnets are found in a number of different industries from manufacturing applications to use in schools, homes and many forms of business. They are found in such a variety of applications and industries because of their ability to be shaped and manipulated, both during and after the manufacturing phase, to fit a specific requirement.

Flexible magnets are typically formed through two different processes, extrusion or calendaring. Deciding between the two different manufacturing processes depends mostly on how the magnet will be cut or manipulated later on in its use. Extrusion is done by squeezing the magnetic material into a mold where it is allowed to cool, forming thin magnetic strips. On the other hand, calendaring is a process in which a magnetic compound is passed through a roller until a magnetic sheet is formed.

The thickness of the magnetic sheet can be manipulated based on the number of times it is passed through the roller. Once the magnetic sheet or strip is completed the cutting can begin. Obviously, if you require a larger flexible magnet, then calendaring may better suit your needs, since it allows you to cut from the larger sheet of magnetic compound rather than the strips that are created through the extrusion process. That being said, the extrusion process is the much preferred method due to its accuracy and efficiency when it comes to flexible magnets.

While flexible magnets offer a number of unique advantages over the more traditional, solid magnets, they are also less durable which makes them a liability in certain applications. The best way to ensure that you receive reliable, flexible magnets is to find a trusted and experienced flexible magnet manufacturer who is able to listen to your application in order to suggest the right solution for you and your applications.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

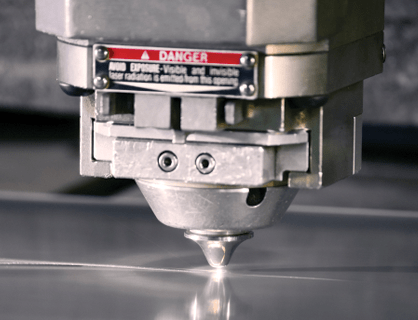

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services