Magnetic Specialties, Inc.

Magnetic Specialties, Inc.Request A Quote

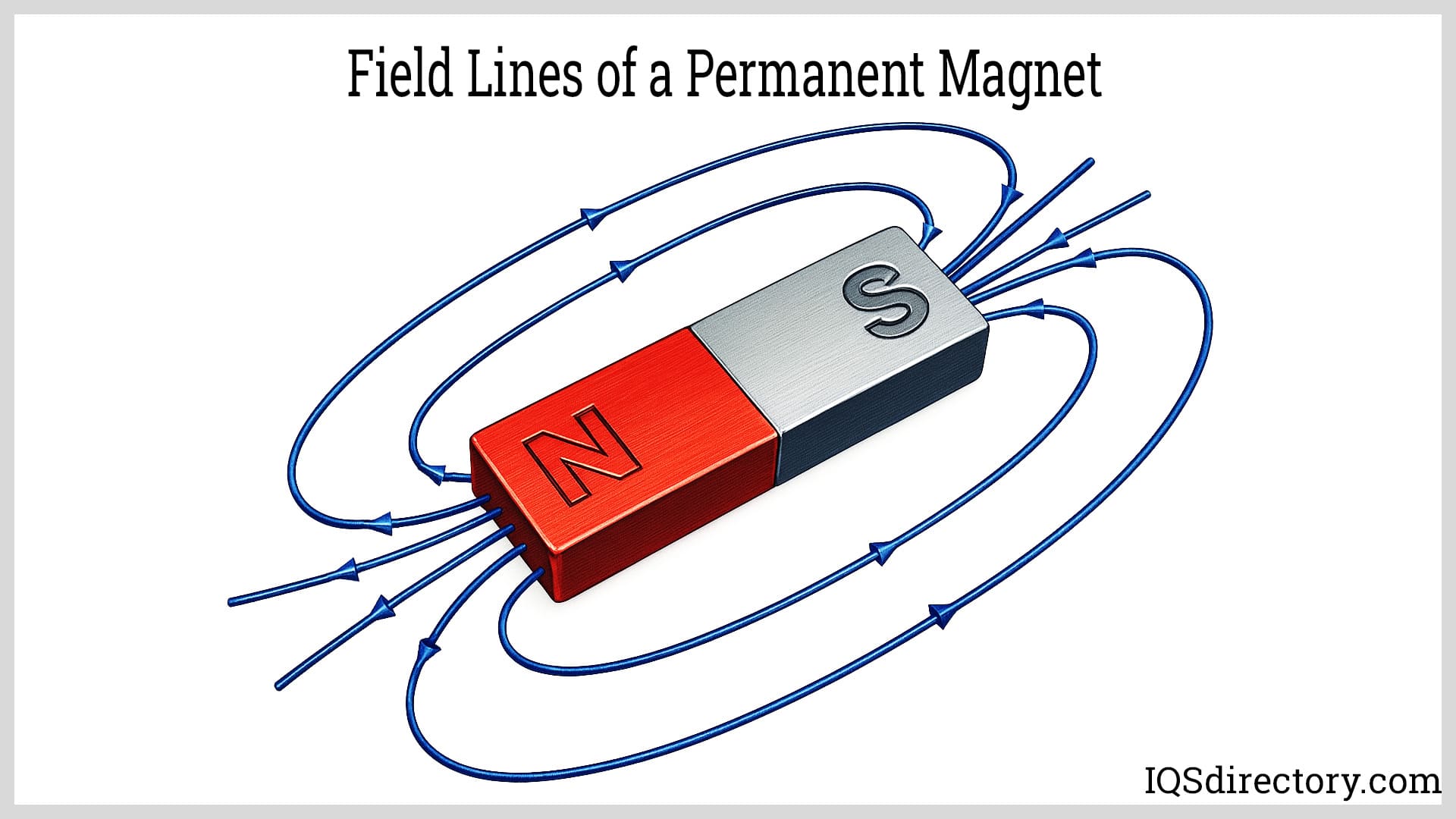

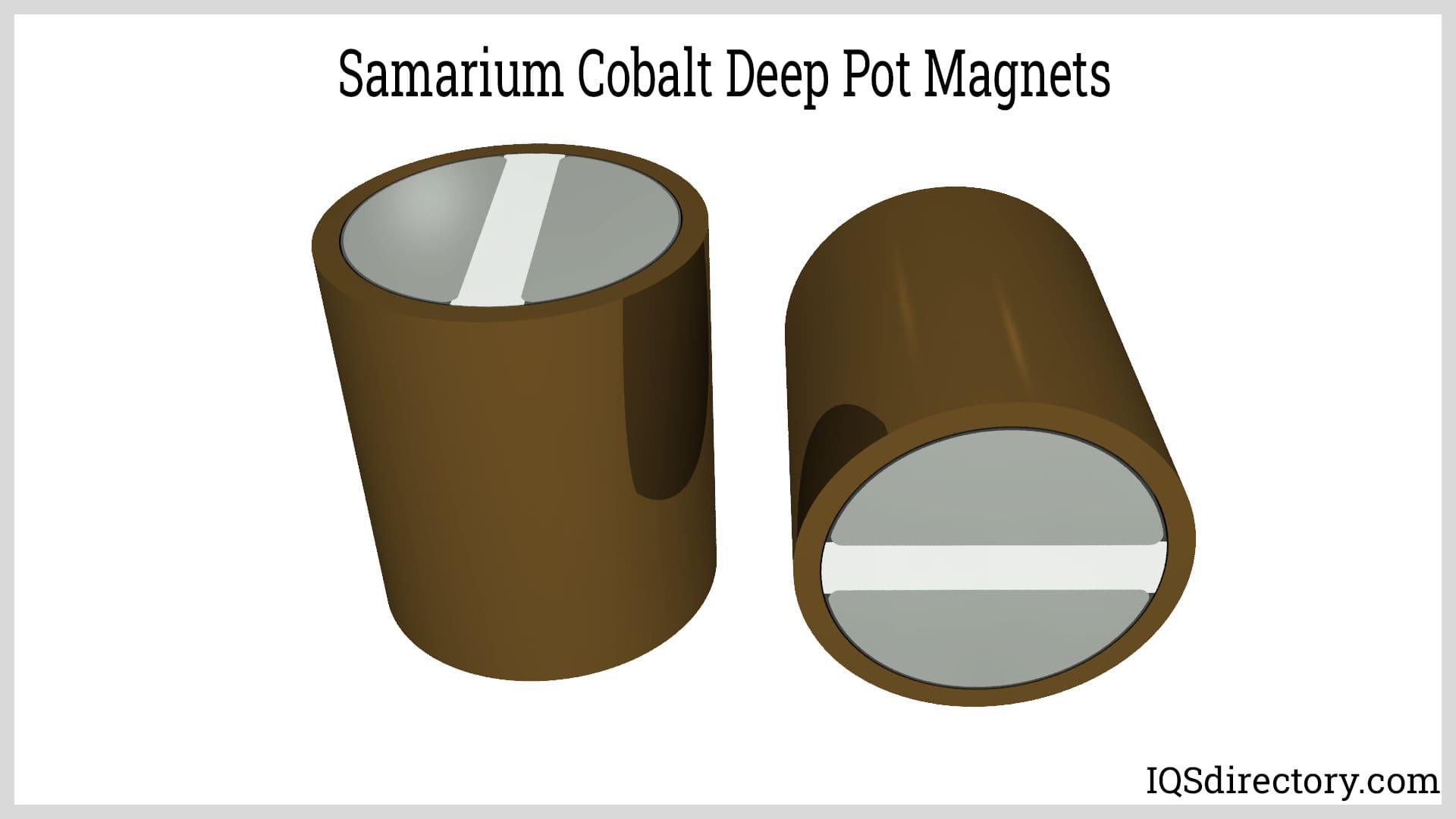

Portland, OR | 971-329-2426Magnetic Specialties, Inc. is a leading provider of magnet assemblies and related services, offering innovative solutions to meet the diverse needs of industries across the globe. With a strong emphasis on quality, precision, and customer satisfaction, we have established ourselves as a trusted partner for businesses seeking reliable magnetic solutions. At Magnetic Specialties, we specialize in the design, development, and manufacturing of magnet assemblies for a wide range of applications. Our magnet assemblies are custom-engineered to deliver optimal performance and functionality in various industries, including automotive, aerospace, medical, electronics, energy, and more. Whether it's a simple magnetic component or a complex system, our team of experienced engineers and technicians work closely with clients to create tailored solutions that meet their specific requirements. Our Magnet Assemblies product line includes a comprehensive range of magnetic components, such as: 1. Permanent Magnet Assemblies: We leverage high-quality permanent magnets, including neodymium (NdFeB), samarium cobalt (SmCo), and ceramic magnets, to design and manufacture assemblies that deliver exceptional magnetic strength and long-lasting performance. 2. Electromagnet Assemblies: Our electromagnet assemblies utilize advanced electromagnetic technology to generate precise and controllable magnetic fields. These assemblies are widely used in applications such as robotics, automation, lifting, and material handling. 3. Magnetic Sensors: We offer a variety of magnetic sensor assemblies, including Hall effect sensors, magnetoresistive sensors, and magnetic encoders. These sensors are crucial for applications involving position sensing, proximity detection, speed sensing, and more. 4. Magnetic Separators: Our magnetic separators are designed to efficiently remove ferrous contaminants from liquids and powders in industries such as food processing, pharmaceuticals, mining, and recycling. These assemblies ensure product purity, enhance safety, and minimize equipment damage. Service Capabilities: In addition to our extensive product offerings, Magnetic Specialties provides a comprehensive range of services to support our customers throughout the entire product lifecycle. Our service capabilities include: 1. Engineering and Design: Our team of skilled engineers collaborates closely with clients to develop custom magnet assemblies that meet their unique specifications. We utilize advanced software tools and simulation techniques to ensure optimal performance and cost-effectiveness. 2. Prototyping and Testing: We offer rapid prototyping services, allowing clients to evaluate and validate the design before full-scale production. Our in-house testing facilities enable rigorous evaluation of performance, durability, and safety to meet industry standards. 3. Manufacturing and Production: With state-of-the-art manufacturing facilities, we have the capability to produce magnet assemblies in large volumes while maintaining high quality standards. Our production processes are optimized for efficiency, precision, and consistency. 4. Quality Assurance: At Magnetic Specialties, quality is of utmost importance. We have a robust quality management system in place to ensure that all our products and services meet or exceed customer expectations. Our quality control procedures encompass rigorous inspections, testing, and adherence to international standards and certifications. 5. Customization and Modification: We understand that each application has unique requirements. Therefore, we offer customization and modification services to adapt our magnet assemblies to specific needs. From altering dimensions and materials to incorporating additional features, we strive to provide tailored solutions. With a customer-centric approach, advanced technology, and a commitment to excellence, Magnetic Specialties, Inc. continues to be a trusted partner for businesses seeking high-quality magnet assemblies and exceptional service capabilities.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

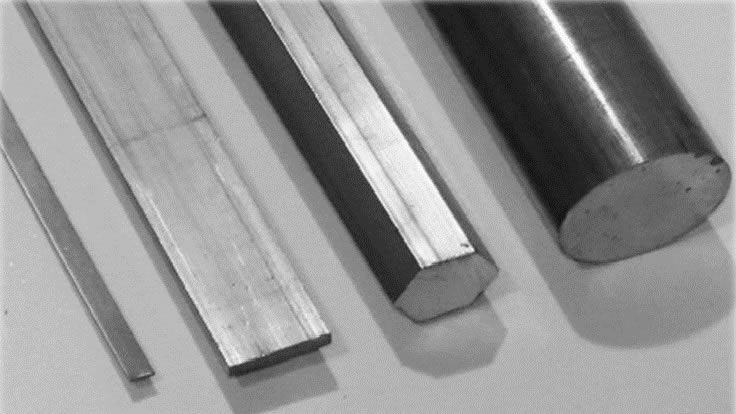

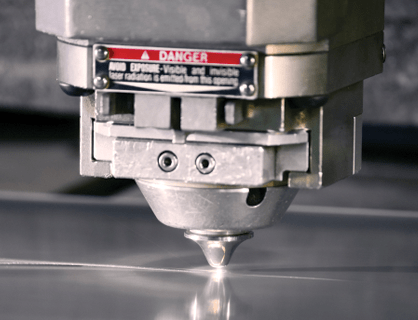

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services