Neodymium is a rare earth element that is known for its strong magnetic properties. Its ability to produce powerful magnetic fields makes it a highly sought-after material for creating magnets. In this article, we will discuss the process of creating neodymium magnets, considerations regarding their creation and use, and the various benefits and applications that they provide. Read More…

Founded in 1895, Arnold Magnetic Technologies is a leading global manufacturer of high performance permanent magnets, electromagnetics, magnetic assemblies, and precision thin metals.

At Applied Magnets, we are dedicated to providing some of the most powerful and reliable magnets available on the market. We specialize in high-grade neodymium magnets which are widely recognized for their unmatched strength and efficiency across a broad range of applications. From advanced engineering projects and industrial machinery to consumer products, scientific research, and educational...

Our customers know they can trust us to provide them with the best magnets in the industry. We supply magnets from only the best manufacturers in the world. We will not offer substandard products or anything that is not the most cost-effective solution.

At TyTek Industries, we are experts in manufacturing magnetic components. Our magnetics catalog include magnetic assembly, alnico magnets, rare earth magnets, and many more. It is our team’s mission to always draw on our strengths and experience to ensure the very best service and quality for our customers. For more information, visit our website or call today!

Magnetic Specialties is a magnet manufacturer of magnet tools for the lifting & handling of materials & parts, industrial recycling and material separation applications. Products include magnetic grates, overhead magnets, tilting magnets, plate magnets, magnetic pulleys, magnetic drums and hoist magnets.

More Neodymium Magnet Manufacturers

The Process of Creating Neodymium Magnets

Neodymium magnets, also known as NdFeB magnets or rare earth magnets, are renowned for their exceptional strength and versatility. The manufacturing process of neodymium magnets is highly specialized and involves several critical steps to ensure the highest quality and performance. Understanding how neodymium magnets are made is essential for engineers, manufacturers, and buyers seeking optimal solutions for industrial, commercial, or consumer applications.

The creation process begins with the mining and extraction of neodymium, a rare earth element, from mineral ores such as monazite and bastnäsite. Once extracted, the neodymium is subjected to a series of advanced purification steps to remove impurities. This step is crucial, as even trace levels of contamination can significantly affect the performance and lifespan of the resulting magnet.

After purification, neodymium is alloyed with iron and boron to form the Nd2Fe14B compound, which is the basis of neodymium magnets. The production of these strong permanent magnets typically involves one of two main processes: powder metallurgy (also known as the sintered process) and rapid solidification (commonly referred to as the melt spinning process).

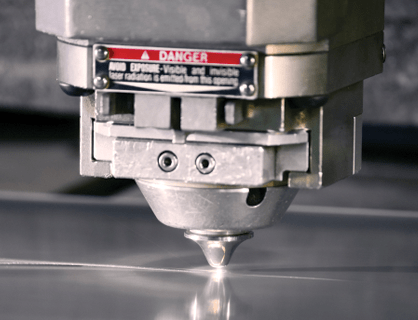

- Powder Metallurgy Process: The alloyed neodymium, iron, and boron are melted and then cooled to form ingots, which are subsequently crushed into a fine powder. This powder is pressed in a magnetic field to align the grains, then sintered (heated without melting) in a vacuum or inert atmosphere to form a dense, solid magnet. The sintered neodymium magnets can be further machined into precise shapes and sizes as required by the application.

- Melt Spinning Process: In this process, the molten alloy is rapidly cooled on a spinning wheel, producing a thin ribbon. This ribbon is subsequently pulverized into powder, which is then bonded (often with a polymer binder) to create bonded neodymium magnets. Bonded magnets offer more design flexibility and can be manufactured into complex or intricate shapes, but they generally have lower magnetic strength compared to sintered magnets.

The choice of manufacturing method is determined by the intended application. For example, sintered neodymium magnets are preferred for high-performance requirements such as electric vehicle motors and wind turbines, while bonded magnets are commonly used in electronic sensors, small motors, and precision medical devices due to their shape flexibility and ease of integration.

Magnetization and Quality Control

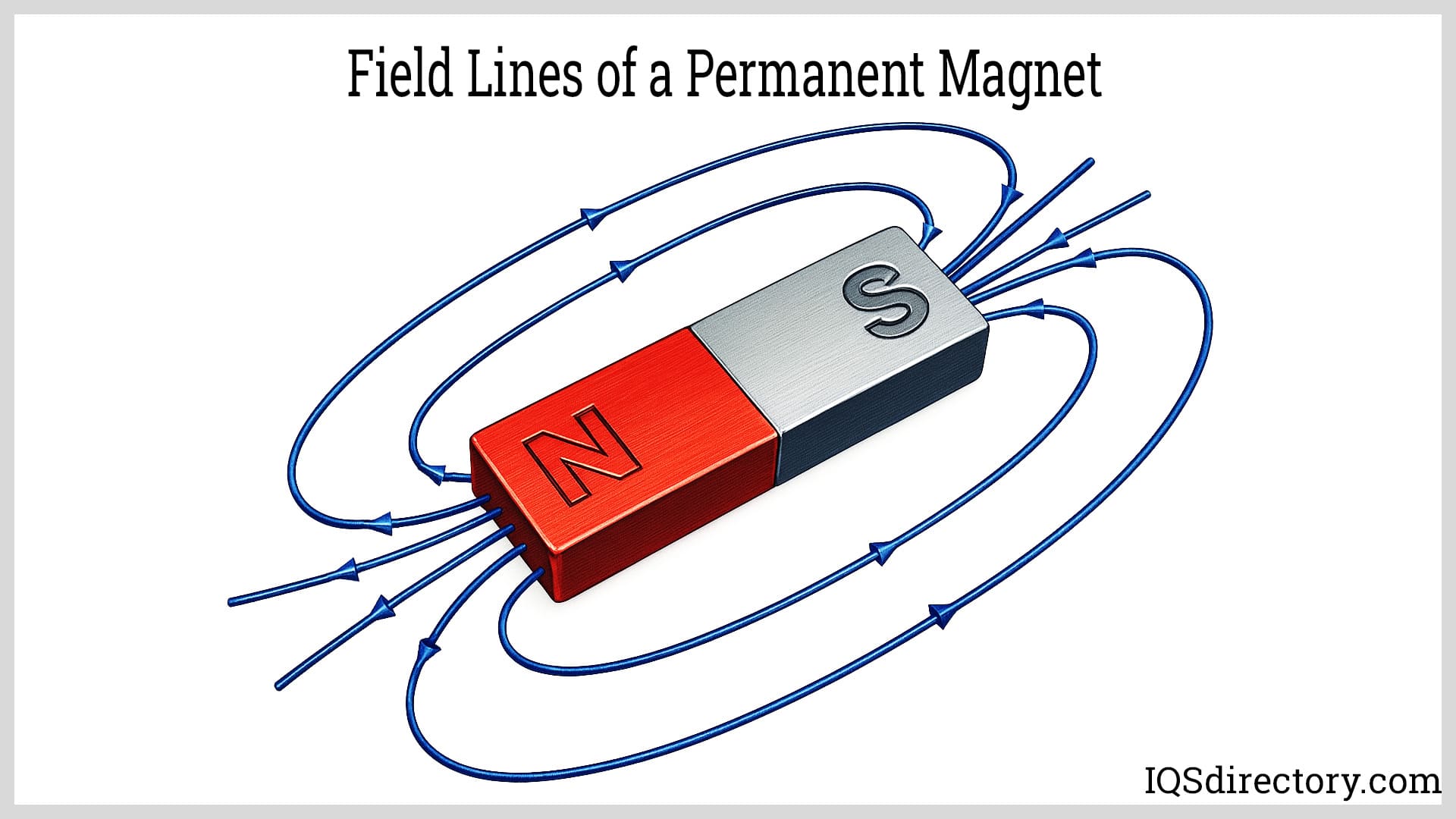

After shaping, the magnets are magnetized by exposing them to a powerful external magnetic field, aligning the magnetic domains and endowing the magnet with its characteristic high magnetic strength. Rigorous quality control protocols, including dimensional inspection and magnetic property testing, ensure that each neodymium magnet meets stringent industry standards for performance, reliability, and safety.

Considerations Regarding Neodymium Magnets

While neodymium magnets offer significant performance advantages, their creation and usage carry important considerations for buyers, engineers, and safety managers. Understanding these factors is key to responsible selection and deployment in diverse industries.

Environmental Impact of Neodymium Mining

The mining of neodymium and other rare earth elements can have substantial environmental impacts. Extraction processes often result in soil erosion, habitat disruption, and groundwater contamination due to the release of toxic byproducts. As sustainability becomes a higher priority for manufacturers and end users, many companies are now seeking neodymium magnet suppliers who adhere to environmentally responsible sourcing and production practices. Are you looking for eco-friendly neodymium magnets? Explore suppliers offering sustainable sourcing, recycling programs, and certifications that demonstrate a commitment to environmental stewardship.

Health and Safety Risks

Neodymium magnets are extremely powerful and must be handled with care. If swallowed or inhaled, they pose serious health hazards, including potential damage to internal organs. Additionally, their intense magnetic fields can interfere with electronic medical devices like pacemakers and can damage magnetic data storage media such as credit cards or hard drives. Safety training and the use of appropriate warning labels are essential when utilizing neodymium magnets in workplaces, laboratories, or consumer products. Wondering how to safely handle neodymium magnets? Consult safety data sheets and best practice guidelines from reputable magnet manufacturers.

Material Limitations and Coating Options

Although neodymium magnets are strong, they can be brittle and susceptible to corrosion if not properly coated. Most commercial neodymium magnets are plated with protective layers such as nickel-copper-nickel, epoxy, or gold to enhance durability and corrosion resistance. When selecting magnets for harsh environments, consider the specific coating options available and consult with suppliers to match the magnet’s finish to your application requirements.

Benefits Provided by Neodymium Magnets

Despite the challenges, neodymium magnets have transformed industries thanks to their unique combination of high magnetic strength, compact size, and versatility. Below, we explore the key advantages that make them the magnet of choice for countless demanding applications.

Unmatched Magnetic Performance

Neodymium magnets possess the highest magnetic energy product (BHmax) among commercially available permanent magnets. This means they generate an exceptionally strong magnetic field even at small sizes. Their superior performance is particularly beneficial for applications where maximizing force while minimizing weight and volume is critical. Looking for the strongest permanent magnets? Neodymium magnets outperform alternatives such as ferrite, alnico, and samarium-cobalt magnets in terms of energy density and coercivity.

High Energy Density

The high energy density of neodymium magnets enables engineers to design compact, lightweight devices without sacrificing power. This characteristic is invaluable for electric vehicle motors, portable electronics, and robotics, where space and weight constraints are paramount. If your project requires miniaturization with maximum output, neodymium magnets offer a clear advantage.

Excellent Corrosion Resistance

With the right protective coatings, neodymium magnets can resist moisture, chemicals, and corrosive environments, extending their operational lifespan. This makes them suitable for use in marine, automotive, and industrial settings where exposure to harsh elements is unavoidable. Need corrosion-resistant magnets? Ask your magnet supplier about available plating and coating solutions tailored to your industry.

Temperature Stability and Custom Grades

Standard neodymium magnets maintain strong magnetic properties up to approximately 80°C (176°F), but specialized high-temperature grades are available for applications that demand stability at elevated temperatures, such as automotive drive motors or aerospace actuators. Understanding the maximum operating temperature and selecting the right grade is crucial for long-term reliability. Not sure which grade of neodymium magnet you need? Compare N35, N42, N52, and high-temp grades to match your performance criteria.

Versatility Across Industries

Neodymium magnets are utilized in a vast array of industries, from renewable energy and automotive to healthcare, electronics, and manufacturing. Their adaptability stems from their small size, high strength, and availability in custom shapes and coatings. Whether you need disc magnets, ring magnets, block magnets, or custom assemblies, neodymium magnets can be engineered to fit virtually any application.

Cost Effectiveness Over Time

Though the initial cost of neodymium magnets is higher than some alternatives, their superior magnetic performance, efficiency improvements, and reduced system size often result in lower total cost of ownership. This makes them a preferred choice for OEMs and product designers seeking to optimize long-term value.

Applications of Neodymium Magnets

The unparalleled properties of neodymium magnets have opened up countless innovative applications across sectors. Below are some of the most common and emerging uses of neodymium magnets, highlighting their value in both industrial and consumer markets.

Electric Motors and Generators

Neodymium magnets are the preferred choice for high-efficiency electric motors and generators, including those used in electric vehicles (EVs), wind turbines, robotics, and industrial automation systems. Their strong magnetic field boosts torque and power density while enabling more compact, lightweight designs. Searching for magnets for EV motors or wind generators? Learn how neodymium magnets can increase system performance and efficiency.

Hard Disk Drives and Data Storage

In computer hard disk drives (HDDs) and solid-state drive actuators, neodymium magnets enable fast, accurate data read/write operations. Their high magnetic strength supports increased data density and faster access times, making them essential components in modern data storage technology.

Magnetic Resonance Imaging (MRI) Machines

Medical imaging relies on powerful, stable magnetic fields. Neodymium magnets are widely used in MRI machines, where their strength and stability enable high-resolution imaging for accurate diagnostics. Their use extends to other medical devices, such as implantable pulse generators and magnetic surgical instruments.

Magnetic Separation and Recycling

Industries such as recycling, mining, and food processing utilize neodymium magnets for magnetic separation. Their strength allows for the efficient removal of ferrous contaminants from products, improving quality control and reducing equipment wear. Looking to improve product purity? Ask about custom neodymium magnetic separators for your production line.

Loudspeakers, Headphones, and Audio Equipment

Neodymium magnets are used in premium audio devices, including headphones, earbuds, microphones, and loudspeakers. Their high power-to-weight ratio allows for compact designs that deliver clear, dynamic sound with excellent fidelity. Consumer electronics manufacturers rely on neodymium magnets for portable, high-performance audio products.

Magnetic Toys, Games, and Educational Aids

Due to their strength and durability, neodymium magnets are popular in magnetic toys, educational kits, and science experiments. These magnets enable creative, interactive learning experiences and are used in puzzles, construction sets, and demonstration tools. Interested in safe neodymium magnets for educational use? Ensure all products meet safety standards and include appropriate warnings for children.

Jewelry Clasps and Fasteners

Neodymium magnets provide reliable, secure closures for jewelry, fashion accessories, and wearable technology. Their small size and powerful hold make them ideal for magnetic clasps, ensuring easy-to-use fasteners that remain discreet yet effective.

Wind Turbines and Renewable Energy

Permanent magnet generators in wind turbines leverage neodymium magnets to convert mechanical energy into electricity efficiently. The use of high-performance magnets reduces generator weight, enhances reliability, and increases overall energy output—key factors for modern wind energy systems.

Marine and Aerospace Engineering

Neodymium magnets are widely used in marine propulsion systems, underwater robotics, sensors, and aerospace actuators. Their corrosion resistance (with proper coatings) and high magnetic strength allow for reliable operation in demanding, space-constrained environments. Considering magnets for aerospace or marine projects? Consult experts about custom shapes, coatings, and grades for extreme conditions.

Consumer Electronics and Mobile Devices

From smartphones and tablets to wearable fitness trackers and laptop computers, neodymium magnets are essential for speakers, microphones, haptic feedback systems, and magnetic charging connectors. Their small size and strength enable innovative, sleek product designs that enhance user experience.

Medical Devices and Healthcare Solutions

The medical field benefits from neodymium magnets in implantable devices, dental tools, drug delivery systems, and magnetic therapy products. Their biocompatibility, stable magnetic properties, and availability in miniature sizes make them a top choice for healthcare technology. Evaluating magnets for medical applications? Work with suppliers experienced in medical-grade neodymium magnets.

Industrial Automation, Sensors, and Robotics

Automation and robotics rely on neodymium magnets for motors, actuators, linear encoders, magnetic switches, and precision sensors. Their consistent performance and adaptability support increased productivity, reliability, and miniaturization in advanced manufacturing environments.

Emerging Applications: Green Technologies and Beyond

As industries pursue sustainability and energy efficiency, neodymium magnets are increasingly used in green technologies such as electric vehicle drivetrains, smart grid power systems, and advanced battery management. Their high performance supports innovation in renewable energy, circular economy solutions, and next-generation electronics.

Choosing the Correct Neodymium Magnet Supplier

With so many variables—magnet grade, strength, shape, coating, and compliance—selecting the right neodymium magnet supplier is crucial to your project's success. A reputable supplier will provide technical support, quality assurance, and customization options tailored to your application. Here’s how to make an informed decision when sourcing neodymium magnets for industrial, commercial, or consumer use:

- Evaluate Experience and Specialization: Use our comprehensive directory of neodymium magnet suppliers to compare companies based on their expertise, production capabilities, and industry focus. Each supplier profile highlights areas of specialization, certifications, and case studies.

- Request Product Samples and Technical Data: Reliable suppliers offer material data sheets, certifications (such as ISO 9001), and representative samples to help you assess magnet performance before committing to a large order.

- Assess Quality Assurance and Compliance: Choose suppliers who adhere to strict quality control protocols and industry standards, including RoHS and REACH compliance for global markets.

- Leverage Customization and Engineering Support: Whether you need custom shapes, sizes, or magnetic assemblies, leading suppliers provide design assistance, rapid prototyping, and application engineering services. Need help specifying the right neodymium magnet? Contact suppliers for expert guidance on grades, coatings, and application requirements.

- Compare Pricing and Lead Times: Use our proprietary website previewer and RFQ (Request for Quote) form to efficiently compare pricing, minimum order quantities, and delivery schedules from multiple neodymium magnet manufacturers. This ensures you receive competitive quotes tailored to your budget and timeline.

By thoroughly researching supplier capabilities, quality standards, and technical support offerings, you can confidently source neodymium magnets that meet your performance, safety, and cost objectives. Whether your application is in clean energy, consumer technology, medical devices, or industrial automation, choosing the right neodymium magnet partner is a critical step toward success.

Frequently Asked Questions About Neodymium Magnets

- What grades of neodymium magnets are available, and how do I choose the right one?

- How do I safely handle and store neodymium magnets?

- What are the best practices for integrating neodymium magnets into my product design?

- Are there eco-friendly or recycled neodymium magnet options on the market?

- How do neodymium magnets compare to samarium-cobalt and ceramic magnets?

- Can neodymium magnets be custom-shaped for unique applications?

- What certifications and compliance standards should I look for in magnet suppliers?

- How do I request a quote or sample from a neodymium magnet manufacturer?

Still have questions or need technical assistance? Contact our team or connect directly with a certified neodymium magnet supplier to discuss your specific requirements, request samples, or obtain custom engineering support. With the right information and a qualified partner, you can unlock the full potential of neodymium magnets in your next project.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services