Many different materials can be utilized to create industrial magnets, including ceramics, neodymium, iron, boron, samarium and cobalt, nickel, aluminum, clay and steel. Each of these materials has differing properties like porosity, magnetic permanence, strength, fabricating manageability and cost, which make certain materials better for specific applications.

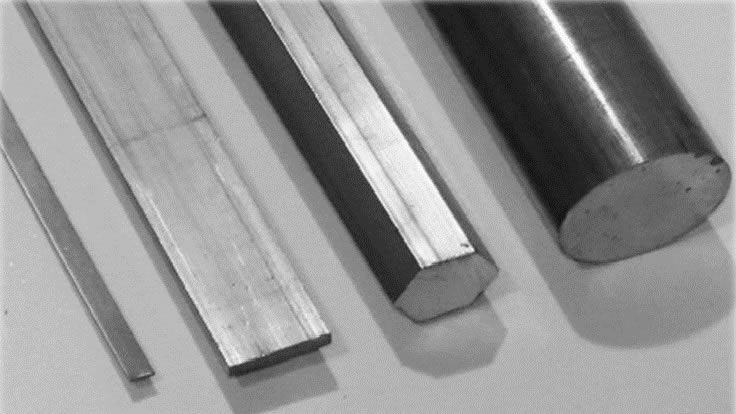

How an industrial magnet is shaped can also effect how it is utilized in certain industries. Bar magnets, which are utilized in the manufacturing of compasses, mobility of scrap metal and integrated into automotive motor systems, are shaped like rectangles regardless of their size. Other shapes involve coils, magnetic strips and even large pieces that resemble sheet metal.

There are two main categories of magnets. Electromagnets, as their name suggests, utilize electric current to generate magnetic fields, and are therefore known as non-permanent magnets. Permanent magnets are magnetic all the time, although the extent of their magnetism sometimes depends on environmental factors such as extreme temperatures and corrosion.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

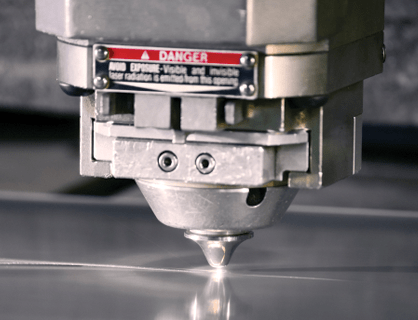

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services